2 M Width Road Milling Machine

Basic Info

Model No.: HD2000

Product Description

2 M Width Road Milling Machine

Crawler Milling Machine /Asphalt Road Milling Machine /Concrete Milling Machine is designed for rebuild and daily maintenance of highway construction . With a strong ability to work and cost-effective, the best structure design, fully meet whole machine strength requirements, traction dynamics requirements and engine thermal management system requirements, with a number of patents

| Item | HD2000 Super |

| Milling Width | 2000 mm |

| Milling Depth | 0-320 mm |

| Tool Spacing | 15 mm |

| Number of cutting tools | 162 |

| Drum diameter with tools | 1060 mm |

| Max. Drum tilt | 5° |

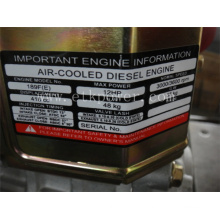

| Engine | CUMMINS |

| Engine Model | QSX15-C600 |

| Engine cooling mode/Cylinders | Water cooling/6 in line |

| Rate Power | 448/600 kw/hp |

| Rate Speed | 0-5.6 km/h |

| Driving Speed | 0-5.6 km/h |

| Working Speed | 0-30 m/min |

| Ground Clearance | 480 mm |

| Driving system mode | Hydraulic |

| Track Number | 4 |

| Track Demension | 1720×300×650 mm |

| Operation Weight | 36000 kg |

| Fuel Tank | 1000 L |

| Hydraulic Oil Tank | 320 L |

| Water Tank | 3300 L |

| Electrical Voltage | 24 V |

| CAN | |

| Conveyor Belt | 800 mm |

| Max. Discharge height | 4800 mm |

| Demension | 14700×2600×3200 mm |

| Min. Inside Steering Radius | 2000 mm |

Product Features

1. HD2000 Super cold milling machine is designed for rebuild and daily maintenance of highway construction . With a strong ability to work and cost-effective, the best structure design, fully meet whole machine strength requirements, traction dynamics requirements and engine thermal management system requirements, with a number of patents

2. Adopts powerful power Cummins production of electric injection engine and high elastic coupling, special gearbox and hydraulic control clutch composition, riding transmission efficiency, compact structure, easy maintenance.

3. The high-elastic coupling installed between the hydraulic control clutch and the engine can fully absorb the unstable impact load generated by the operating resistance, effectively improving the service life of the engine, clutch and Other power components.

4.Adopts world famous CAN-bus based network control system. The whole machine has the following special functions:

A. Automatic control of road surface milling and planing process and monitoring of working conditions

B. Automatic regulation and distribution of engine power in the process of pavement milling and planing

C. Intelligent steering control, which can provide front and rear wheels .Choice of five steering modes: full wheel and manual

D. Automatic leveling and vital control

E. Flexible system control parameter setting and system sensitivity adjustment setting

F.Real-time fault diagnosis and recording of power system, hydraulic system and electronic control system

G. The graphical display interface makes the operation of the machine more intuitive, convenient and easy

H.The control system communicates with the electric injection engine through J1939 protocol, realizes the digitalization of engine instruments, displays and records more engine fault alarm information, and adjusts the fuel supply of the hole-punch machine in real time according to the actual power demand of the milling and planing operation, so as to save fuel and reduce exhaust emissions

5. The operating platform can slide left and right and rotate 360 degrees, so that the driver can adjust the driving position according to the operation needs, which is convenient for operation

6. The cutting depth setting device installed on both sides of the machine can display and set the milling depth on both sides at the same time, which is convenient to operate

7. The use of transverse slope sensor can meet the requirements of special milling and planing conditions, and improve the applicability of the machine

8. The column lifting system is equipped with electronic and hydraulic dual protection functions to prevent misoperation and improve the safety of machine operation

9. The hydraulic system adopts international first-class quality hydraulic pump, hydraulic motor, control valve and other components

10. High quality hydraulic oil and its cleanliness control system ensure the reliability and durability of the machine system

11. The milling and planing rotor equipped with a fast cutter base system has a stronger structure and is easy to maintain

12. With patented technology protection of the milling plane rotor frame design, installed with wear-resisting lining board, to extend the service life

13. The sprinkler system is equipped with a speed regulating device in the hydraulic valve set, which is convenient to adjust the pressure and flow of the water pump to meet the needs of various occasions

14. High quality crawler rubber sheet enhances the traction capacity of the machine and improves the service life of the crawler system.

Also,we have Asphalt Distributor,Road Synchronous Chip Sealer,Road Surfacing Maintenance Truck,Asphalt Production Plant,Road Surfacing Maintenance Machine and so on.

Product Categories : Milling Machine